What are slatted floors?

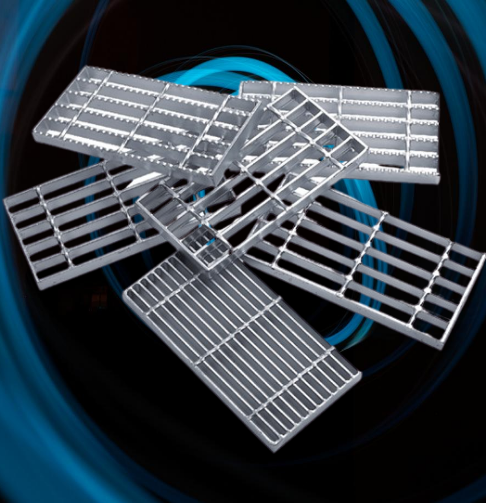

Floorings are metal coverings that are intended for use in industrial areas, commercial premises, residential and office buildings and other facilities. Such coatings are designed to accommodate production equipment and personnel. Thanks to their lattice design, they keep the premises clean and also ensure the safe movement of people on platforms or scaffolds. Steps are also supplied with the grating. Arc Engineering is the best slatted floors manufacturer in Pune.

Features of gratings

The grating is a set of longitudinal (beams) and transverse (bars) steel elements, which are connected to each other by welding or by pressing into slots. All loads are perceived only by beams, and twisted bars are needed to connect all elements into a single structure. In industry and other industries, the following types of gratings are used: welded; pressed; cut profiled.

Such coatings are distinguished by ease of delivery and installation, and also meet all modern aesthetic and technical requirements. Welded and pressed floorings are the most widely used, as they have a number of advantages in comparison with other coatings made of metal or other materials.

In the process of manufacturing welded and pressed flooring, black (St3) or stainless (08X18H10, 10X17H13M2T and some others) steels are used. In the first case, in order to provide the necessary anti-corrosion characteristics, a layer of zinc is applied to the metal surface (hot or cold galvanising). Stainless steel decks are lighter and therefore easier to install.

Floor welded gratings are made in the form of individual mats 6100 × 1000 mm in size or on an individual order as an integral coating. Thanks to this, if necessary, you can always replace a failed element or repair a damaged area. Because grating can be modular, the most complex arrangements can be easily created.

What is the difference between welded grating and pressed

Pressed and welded gratings are coverings of a similar design. In both cases, carrier strips and cross bars are used. The differences are only in the way of connecting the structural elements of the grating.

Bearing strips and connecting rods of welded structures are connected using forge-and-press welding. Twisted bars are fastened with longitudinal elements under pressure up to 1000 kN and simultaneous electric welding of 2500 kVA. At the same time, unlike pressed flooring, no slots are made in the bearing strips, which significantly increases the rigidity of the entire structure.

In pressed gratings, the load-bearing beams have conical or shaped slots into which the transverse elements are pressed under high pressure. Thus, it is possible to create a strong and rigid structure that can be used for a long time. All loads are evenly distributed over the surface of the deck and provide the ability to manufacture coatings of various shapes and sizes without compromising performance.